Hemp Extract Is The Key Ingredient

If you want to know whether a hemp product is any good, you have to understand how hemp extract is made. That’s because what happens between the farm and the final bottle determines whether you’re getting a therapeutic, plant-rich experience—or something that’s been stripped of nearly all its natural value.

Most hemp extracts on the market today are heavily processed, chemically refined, and made from poor-quality starting material. The result? You’re often left with a product that’s closer to CBD isolate than true hemp.

In this post, we’ll break down how hemp extract should be made—step by step—and where most companies go wrong.

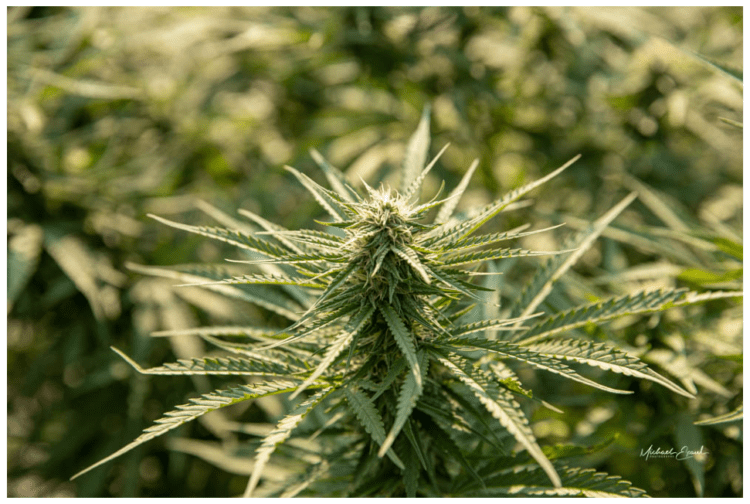

It All Starts With the Hemp

You can’t make a great product from bad hemp. No matter how advanced the extraction method is or how fancy the branding looks, if the plant itself wasn’t high-quality to begin with, the final product is going to fall flat.

The best hemp is grown organically—without synthetic pesticides or fertilizers—and carefully selected for its resin-rich flowers. That resin is where the therapeutic compounds live: cannabinoids, terpenes, flavonoids, and more. Without it, there is no real medicine in the plant.

Yet many companies still use industrial biomass: the entire plant including the inert stalks and branches. It requires less resources so it’s cheaper—but it’s not hemp in its most beneficial form.

Harvesting: Hand vs. Machine

Once the hemp is grown, it has to be harvested. But how it’s harvested matters a lot.

The flowers—the part of the plant richest in cannabinoids and terpenes—are delicate. They’re coated in tiny, crystal-like trichomes that contain the active compounds. The more carefully you handle them, the more you preserve.

Hand-harvesting allows growers to handle the plants with care, preserving as much resin as possible. Industrial operations, on the other hand, often use combines to mow down entire plants and shred everything together—stems, stalks, and all.

This rough process damages the flowers, contaminates them with unwanted plant parts, and sets the stage for low-quality oil that will need heavy refinement later just to be usable.

Drying: A Make-or-Break Step

Drying hemp is a balancing act. Done right, it locks in the plant’s chemistry. Done wrong, it can ruin the product before it even gets extracted.

Dry too slowly, and you risk mold. Dry too fast—especially under high heat—and you can destroy the very compounds you’re trying to preserve.

We believe in slow, controlled indoor drying where temperature and humidity can be monitored. Unfortunately, many companies either hang their plants in open barns, leave them in the sun, or use kilns—essentially giant ovens—that cook off the volatile oils and ruin the flower’s integrity.

At this point, the original potential of the plant is often lost. But most producers keep going anyway.

Extraction: Where Most Products Fall Apart

Extraction is where you turn dried hemp flower into an oil that people can actually consume. And it’s also where many companies sacrifice quality for yield.

There are multiple extraction methods but ethanol and CO2 extraction are the most common.

- Ethanol and Supercritical CO2: These are the most common methods used in the industry. They’re fast, cheap, and pull out a lot of material—but not always the good kind. Because most hemp used in these systems is low quality, the extract that comes out usually smells, tastes, and looks bad. So it’s distilled and refined repeatedly until it’s barely recognizable as hemp.

- Subcritical CO2: This is the method we use. It’s a lower temperature, lower pressure version of CO2 extraction that gently pulls out cannabinoids, terpenes, and other beneficial compounds without destroying them. It doesn’t require post-processing or refinement—meaning the final oil is more true to the plant. The catch is that you must use high quality inputs which is why this method is rarely used by others.

A common misconception is that supercritical CO2 is superior to ethanol. But the truth is, both methods often end up relying on alcohol-based refinement anyway. The original plant material just isn’t good enough to stand on its own.

So if you’re buying a “full spectrum” oil that’s been refined and stripped, what are you really getting?

Why Most Hemp Products Aren’t Really Hemp

Let’s be honest: by the time most hemp products hit the shelf, there’s very little hemp left in them.

You started with poor-quality biomass. You crushed it during machine harvest. You dried it poorly or cooked it in a kiln. You blasted it with high-pressure solvents. Then you refined and distilled it until all that was left was cannabinoids in a carrier oil.

Sure, that might still be technically called a “hemp extract.” But it doesn’t contain the natural spectrum of compounds that give the plant its therapeutic effect. It’s not true to the plant—and that’s why so many people try hemp and feel… nothing.

How We Do It Differently at Western MA Hemp

We don’t chase yield. We chase quality.

At Western MA Hemp, our goal is simple: preserve the natural chemistry of the hemp plant. That means:

- Grown organically in Western Massachusetts soil

- Hand-harvested to protect resin-rich flowers

- Indoor dried for full preservation of terpenes and cannabinoids

- Subcritical CO2 extraction—no high heat, no harsh solvents

- Zero refinement—our oil is ready as-is, just as nature intended

The result is a true-to-the-plant extract that captures the full flavor, aroma, and therapeutic potential of hemp. And because we work with different strains, you can choose the experience you want—daytime clarity, anytime balance, or evening relaxation—without the need for additives or synthetic flavorings.

Final Thoughts: If It’s Not Made Right, It Won’t Work

Hemp is a powerful plant—but only when you treat it with care. Every step of the process matters, and most companies cut corners at every turn.

So if you’ve tried hemp products that didn’t work for you, it might not be your fault. Chances are, what you used wasn’t really hemp in the first place.

Next time, look beyond the label. Ask how it was made.

And if you want hemp the way nature intended—untouched, unspoiled, and full of life—we’ve got you covered.

FAQ: How Hemp Extract Is Made

What is hemp extract?

Hemp extract is an oil made from the resin of the hemp plant. It contains cannabinoids like CBD, as well as terpenes, flavonoids, and other beneficial plant compounds. When made properly, it reflects the full chemical profile of the hemp flower it came from.

Does it matter how hemp is harvested and dried?

Absolutely. Harvesting and drying are two of the most critical steps. Machine harvesting damages the flowers and mixes in unwanted parts, while improper drying can mold the product or burn off all the good stuff. If the resin gets degraded here, there’s not much left to extract later.

What’s the difference between subcritical and supercritical CO₂ extraction?

Subcritical CO₂ uses lower temperatures and pressures to gently extract the good stuff—like cannabinoids and terpenes—without destroying them. Supercritical CO₂ is more aggressive, often used on lower-quality material, and usually requires extra refinement that strips away what makes the plant effective.

Why do so many companies use ethanol or supercritical CO₂?

Because it’s cheaper and faster. These methods allow them to process large volumes of low-quality hemp. But the trade-off is that the resulting oil usually needs to be heavily refined, which removes much of the plant’s natural benefit.

Is “full spectrum” always full spectrum?

Not even close. Most products labeled full spectrum are just CBD with trace THC and none of the other plant compounds. Real full spectrum should include a wide range of cannabinoids and terpenes—just like the flower itself.

Why does the quality of the starting hemp matter so much?

You can’t extract what isn’t there. If your hemp flower didn’t have rich resin full of cannabinoids and terpenes to begin with, the final oil won’t either—no matter how fancy the extraction process sounds.

How can I tell if a hemp extract is high quality?

Check the lab test. A real full-spectrum extract will show more than just CBD and THC. Look for cannabinoids like CBG, CBC, and CBDA—and especially terpenes. If there’s no terpene profile on the test, odds are it’s been refined down to almost nothing.